Kamra’s specialised knowledge in the area of hardmaterials component design and manufacture is a culmination of materials science and metallurgical know how combined with our second generation of toolmaking and manufacturing experience. Selecting the best hardmaterials for any particular application is where experience matters.

Coldworking Tool Steel

Broad range of applications. Often used for packaging machinery knives for Fast Moving Consumer Goods FMCG industries and numerous industrial applications for cutting, stamping and moulding. Special coatings can be added to an already hardened component to extend the wear life even further.

Solid PM Steel & HSS

Apart from metal cutting tooling applications, these materials can be used for high speed packaging wear parts, machinery knives for FMCG industries and a number of heavy industry applications. Best suited to stable dynamic conditions with minimal vibration and variability requiring good cutting edge integrity and structural toughness.

Solid Ceramic & Carbide Steel Combinations

There are a narrow range of applications for this very high wearing but brittle used material in the Fast Moving Consumer Goods Industries and industrial applications for wearing surfaces. While best suited to static or low vibrations applications certain formulations of ceramic can be adapted to offer some toughness.

Stainless Steel & Aerospace Aluminium

A broad range of applications, used in FMCG industries due to sanitation properties for contact with food and medicines and for corrosive environments in industrial applications.

Applications requiring structural toughness and low mass, used principally for aerospace, defence, automotive applications with some applications in the FMCG sector.

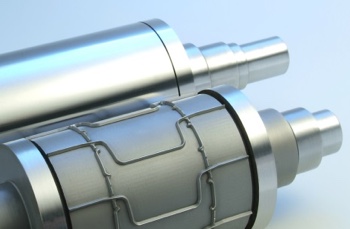

General Engineering Steels

General requirements of industry such as shafts, gears, couplings etc.